How Do Metal Plate Cutting Machines Work?

What is a Metal Plate Cutting Machine?

A metal plate cutting machine is an industrial tool designed to cut, shape, or engrave different types of metal sheets with precision. These machines are widely used in industries such as construction, automotive, shipbuilding, and aerospace. Depending on the cutting method, they can handle mild steel, stainless steel, aluminum, copper, and other alloys. The goal of a metal plate cutting machine is to achieve clean, accurate cuts while reducing material waste and improving production efficiency.

How Do Metal Plate Cutting Machines Work?

Metal plate cutting machines use different technologies to slice through metal sheets, including mechanical force, heat, or high-energy beams. The working process usually involves:

Feeding the metal sheet – The sheet is placed on the cutting bed.

Programming the design – Operators use CAD/CAM software to input the cutting pattern.

Cutting process – Depending on the machine, cutting may be done through:

Laser beams that melt and vaporize the metal.

Plasma arcs that generate extremely hot plasma to cut through thick metals.

Mechanical shearing or punching for simpler applications.

Finishing – After cutting, parts may require deburring, polishing, or bending for final use.

This automation ensures high precision, repeatability, and faster production cycles compared to manual cutting methods.

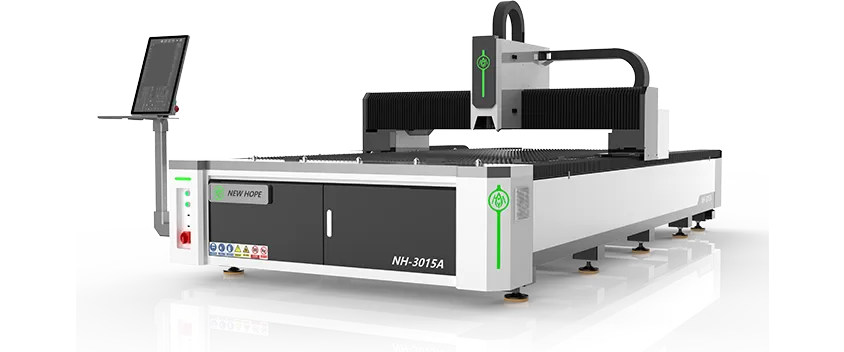

Laser Cutting Machine for Metal Sheets

A laser cutting machine for metal sheets is one of the most advanced and popular tools in modern fabrication. It uses a high-powered laser beam to cut through metals with extreme precision and minimal distortion. Key benefits include:

High accuracy – Laser cutters can achieve tight tolerances and detailed shapes.

Smooth edges – Cuts require little to no finishing.

Flexibility – Capable of cutting thin and thick sheets, as well as engraving.

Automation – Compatible with CNC systems for mass production.

Laser cutting machines are ideal for industries requiring fine detailing, such as electronics, jewelry, automotive components, and custom metal fabrication.

Laser Cutter vs Plasma Cutter for Metal

When choosing between a laser cutter vs plasma cutter for metal, consider the following differences:

Cutting speed: Plasma cutters are faster for thick metals, while laser cutters excel with thin and medium-thickness sheets.

Precision: Laser cutters offer higher precision and smoother edges, suitable for detailed designs.

Cost: Plasma cutting machines are generally more affordable but less accurate.

Materials: Both can cut steel, stainless steel, and aluminum, but laser machines handle delicate and complex work better.

In summary, laser cutting machines are ideal for high-precision jobs, while plasma cutters are more cost-effective for heavy-duty cutting.

Sheet Metal Cutting Machine Prices

The price of sheet metal cutting machines varies greatly depending on the cutting technology, power, and brand:

Entry-level plasma cutters: $2,000 – $10,000

Industrial plasma cutting systems: $20,000 – $80,000

Entry-level laser cutting machines: $10,000 – $50,000

High-power CNC laser cutters: $80,000 – $300,000+

Additional costs may include installation, training, software, and maintenance. Buyers should balance budget with production needs to ensure a good return on investment.

How to Choose a Metal Plate Cutting Machine

Choosing the right metal plate cutting machine depends on several factors:

Material type and thickness – Laser for thin sheets, plasma for thicker plates.

Cutting precision requirements – Laser is better for intricate designs.

Production volume – High-output factories should invest in automated CNC models.

Budget and ROI – Consider both machine price and long-term operational costs.

Support and maintenance – Select a reliable brand with strong after-sales service.

By analyzing these aspects, businesses can select the most suitable machine for their operations and maximize efficiency.

Conclusion

A metal plate cutting machine is essential in modern metalworking industries, offering precision, speed, and efficiency. From laser cutting machines for high-accuracy work to plasma cutters for heavy-duty applications, the right choice depends on your production needs and budget. Understanding how these machines work, comparing technologies, and evaluating costs will help you invest in the most suitable solution for your business.